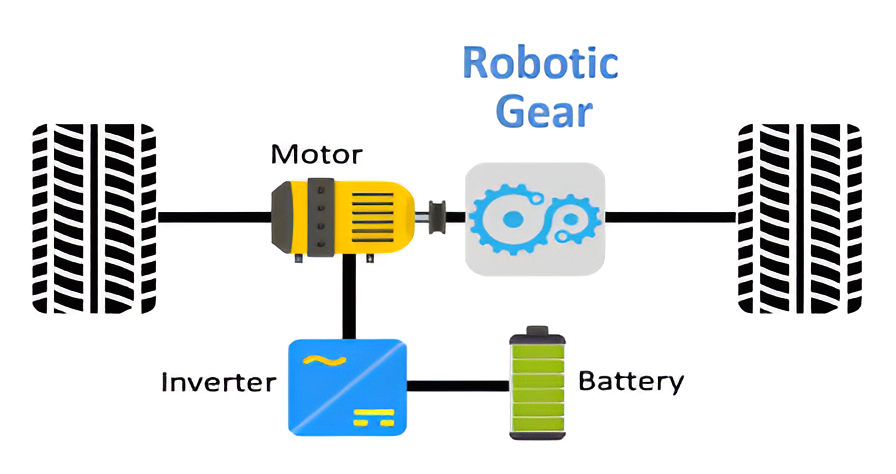

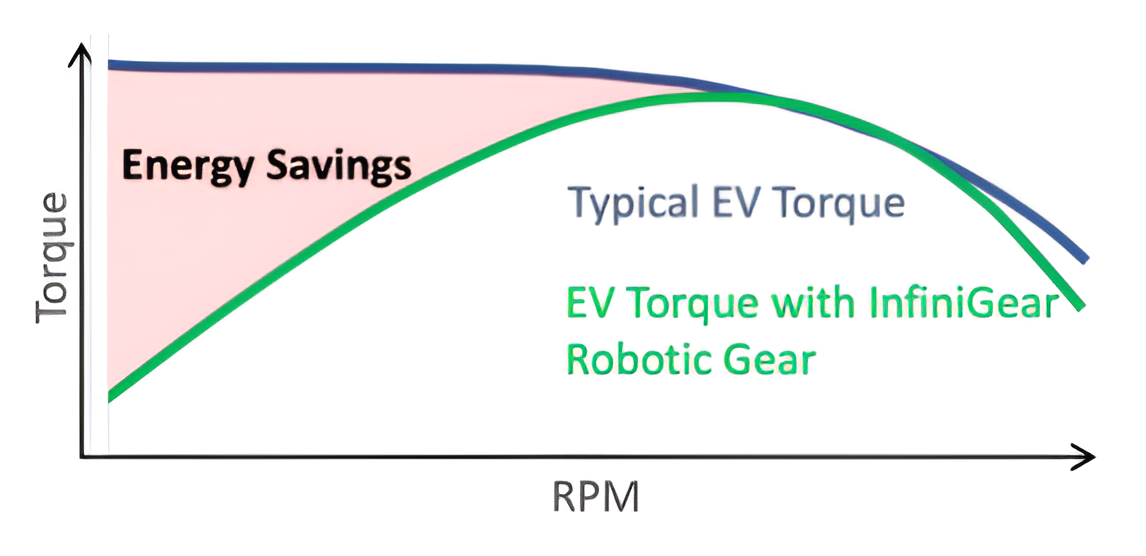

Harness torque and reach 98% gearbox energy efficiency for increased EV range.

The iGear system (C) is the only patented robotic gear system to provide unlimited gear ratios to deliver both torque and speed, with 98% efficient energy transfer. The system uses AI to optimize energy savings during operation.

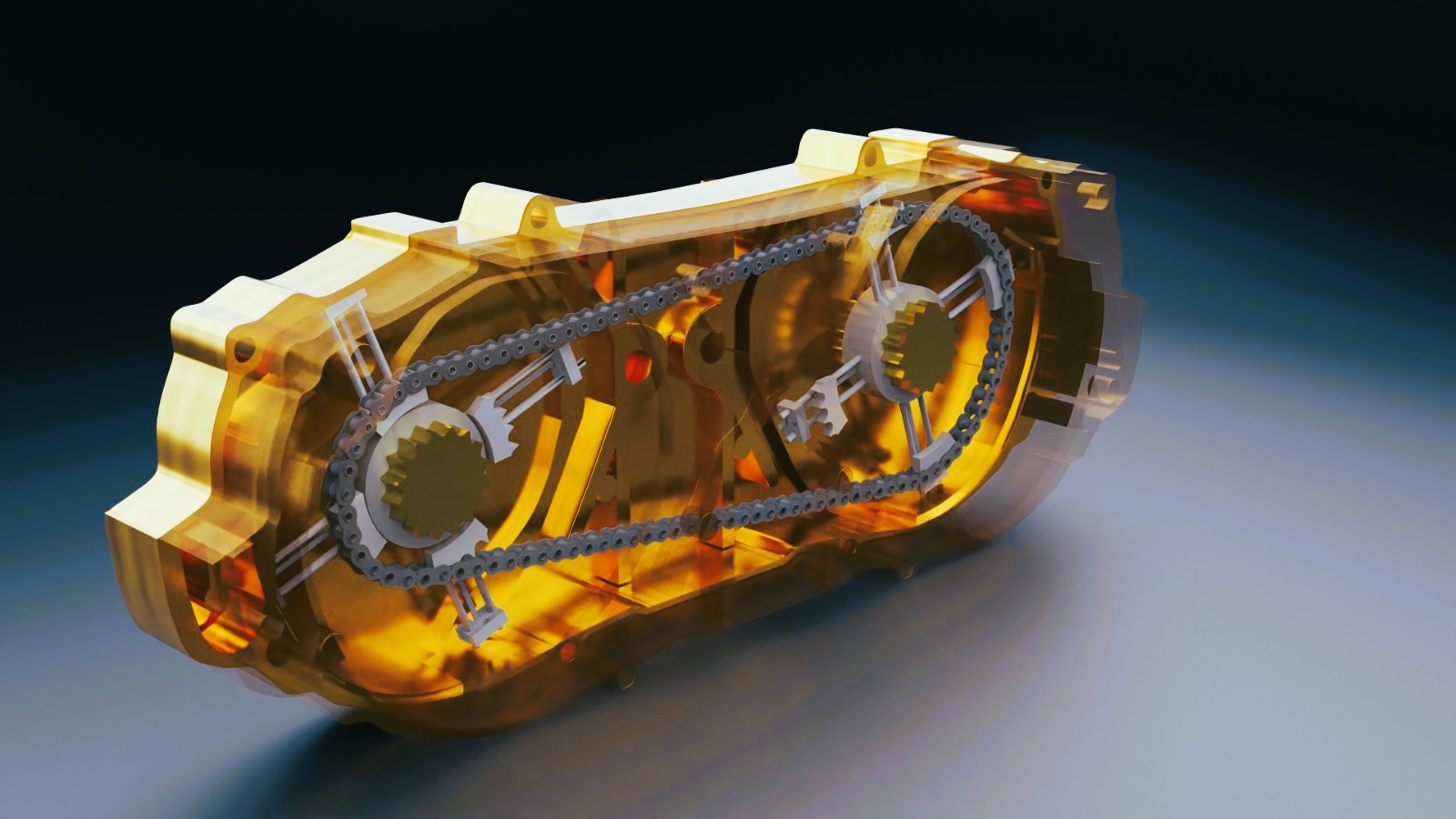

The dynamic iGear system (C) ensures optimal drive train energy transfer while harnessing torque … with 1/3 less weight.

Yesterday’s technology won’t solve today’s EV challenges. iGear system (C) wide range of gear ratios and simple design optimize energy transfer.

iGear system (C) replaces traditional gearboxes with a robotic gear that offers a nearly infinite range of gear ratios.

The iGear system (C) works with all sizes of gearbox applications, from small aeronautical transmissions to heavy trucks and wind turbines.

Learn more about how iGear system (C) works with nearly any gearbox application.

Learn how iGear system (C) can dramatically increase torque and increase range or reduce battery weight.

Learn how the iGear system (C) can replace most traditional gearbox assemblies.

Learn how iGear system (C) can reduce weight to reduce cost and increase range.

We are looking for people who think outside the gearbox! Qualified investors can learn more about InfiniGear here:

Do you want to work on an engineering team that changes the world? Connect with us to learn more!

We are committed to creating a diverse environment and are proud to be an equal opportunity employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, gender, gender identity or expression, sexual orientation, national origin, genetics, disability, age, or veteran status.